Oil flushing is a term used to describe a variety of activities related to removing lube system contamination and cleaning the internal components of your system.

There are several types of oil flushes, from more complex high velocity oil flushing projects to hydraulic system flushing or a simple flush with a small filter cart. To select the proper oil flushing method, you should consider the overall plant objectives, the types of contaminants in the system, and the condition of the lube system components.

To Flush or Not to Flush

When done effectively, oil flushing is a high-value maintenance practice for your machines. Restoring system cleanliness can add years of life to your equipment. However, oil flushing is a disruptive practice to any lube system and carries significant risk if not performed properly. Determining if your system needs a flush is the first step.

There are many situations when oil flushing is required, including:

- when commissioning new machines.

- when re-commissioning machines that have been idle.

- after a system component fails and leaves broken pieces in the lube system.

- after a filter collapses and releases contaminants back into the system.

- when an incompatible fluid has been inadvertently added to the system.

- when changing to a new lubricant brand or formulation and the compatibility is not understood.

- when oil degradation products, such as sludge and varnish, are in the system

Unless there is a catastrophic failure, the most common time when turbine oil users contemplate a flush is between oil changes. But is a flush required each time you change your turbine oil? There is not an industry-accepted practice for determining this.

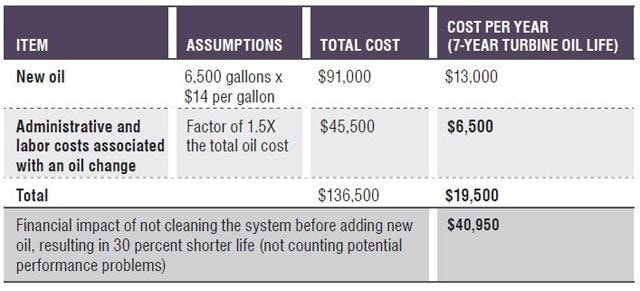

Removing degraded oil and deposits from the internal components of your lube system before charging your system with new oil certainly seems to make sense. You wouldn’t want to take a bath in a dirty bathtub. However, oil flushing can be costly. Is it really necessary?

Flushing is not required:

- between oil changes, if the lubricant system is free of sludge, varnish, and other deposits.

- when most of the old oil can be removed from the system.

- when the new turbine oil is of the same type and brand as the in-service oil

- when extensive compatibility tests have verified the new oil’s compatibility.

On the other hand, flushing between oil changes should be performed when:

- there are indications that sludge, varnish, or other deposits may be in the system.

- the current in-service oil is in poor physical or chemical condition and it is not feasible to remove more than 98 percent of the oil from the system.

- the new charge of oil will be a different formulation that may not be compatible with the current in-service lubricant.

Impact of Putting New Turbine Oil into a Contaminated System

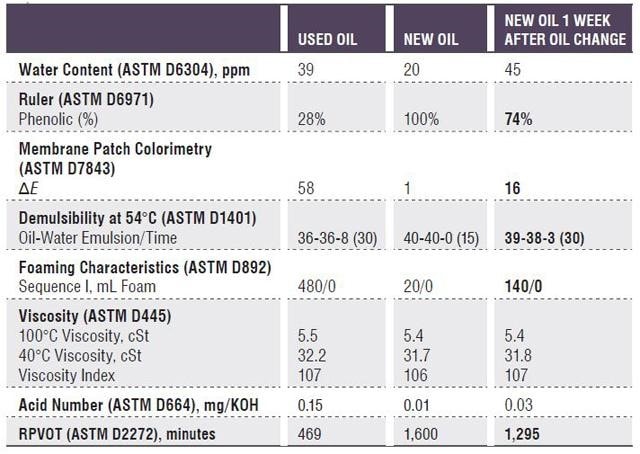

Since the primary mode of turbine oil failure is oxidation, the life and performance of a turbine oil will be dependent upon the health of its antioxidant system. Recharging a dirty lube system with new oil can have a significant impact on the life and performance of this new oil. Oil degradation products are reactive species that will rapidly deplete the fresh antioxidants. Other properties such as acidity, water separability, and foam inhibition can all be impacted by residual varnish and sludge in the system.

A Large-Frame Gas Turbine Reservoir

When the oil in a large-frame gas turbine was changed, an oil flush was not performed. The used oil was degraded, and the plant experienced valve performance problems because there was varnish present in the system. The impact of not adequately cleaning the system prior to recharging with new oil is shown in the tables below.

Understanding the Reactivity of Varnish Components

A simple experiment was set up to understand the reactive nature of varnish and the impact it has on new oil. A filter that contained significant varnish deposits was first rinsed with petroleum ether to remove the oil, leaving the varnish on the media. The varnish-loaded media was then placed in a beaker of new oil and allowed to mix for one day. Fourier transform infrared (FTIR) analysis was then performed on the oil after 48 hours. The oil changed color significantly and dissolved some of the varnish components in the filter. The addition of degradation products to the oil could also be seen on the FTIR spectrum.

The analysis revealed that a significant concentration of amine antioxidants was lost from the new fluid. This experiment demonstrated the negative impact degradation products can have on new oil additives.

Options for Flushing Turbine Oil Systems

While a number of different oil flushing techniques can be employed, two of the most common and important to understand are chemical flushing (also called chemical cleaning) and mechanical oil flushing (also called high velocity oil flushing).

Chemical Flushing

With this method, surface-active chemistry is used to remove varnish and sludge from the system. The surface-active cleaning agent is typically an oil-soluble solution composed of a naphthenic base with detergents, dispersants, and corrosion inhibitors. The surface-active agent is often added to the in-service turbine oil 48 hours before the outage at a rate of 10 percent. Supplemental filtration is usually required to handle the high amount of contamination that is released during the flush.

The in-service oil and cleaner are then drained from the system, and a sacrificial flushing oil is used to rinse the remaining cleaner from the system. Frequently, multiple partial charges of flushing oil are needed to adequately dilute the cleaner in the system. Sometimes water-based fluids with cleaners are employed as the flushing fluid.

Mechanical Flushing

When performing a mechanical flush, heated oil is pumped at a high velocity throughout the system using external pumps. The flow rates are typically three to four times the normal flow rate and require a minimum Reynolds number of 4,000 to achieve turbulent flow.

Bearing jumpers are installed to increase bearing supply and return flow rates as well as to protect bearing surfaces from abrasive contaminants. Other components such as system headers and valve blocks are also isolated from the flush. Supplemental side-stream filters (typically bag filters) are installed to collect contaminants pushed out of the system from the turbulent

oil flow. Manual cleaning of components often accompanies a mechanical flush.

Conclusion

Oil flushing’s main focus is to remove lubrication system contaminants and clean internal components. Even though this can seem like a daunting task, with the right preparation and understanding, oil flushes can provide many benefits to your system, including better overall function. There are a multitude of ways to restore lubrication system cleanliness, but by taking into account the plant’s overall objectives, you can successfully choose the best option for your plant needs.