Imagine your machinery running smoothly, day in and day out, without the threat of unexpected breakdowns or costly repairs. The secret to this seamless operation is effective lubrication. Lubrication is the lifeblood of rotating equipment; without it, the moving parts can quickly wear down, leading to significant downtime and expense. According to Noria Corporation, U.S. manufacturers could save up to $1.5 billion dollars (cumulatively) a year by improving lubrication practices, thanks to reduced downtime, fewer repairs, and longer equipment life. Your role in implementing these practices could make a significant impact on your company’s financial health.

In various industries—from manufacturing plants to farming operations and lumber mills—your expertise in proper lubrication management is crucial. That’s why lubrication and fluid management are essential across these sectors. There are many benefits of partnering with external lubrication specialists. These experts can help ensure your equipment not only performs optimally but also runs longer, safeguarding your investments and boosting your bottom line.

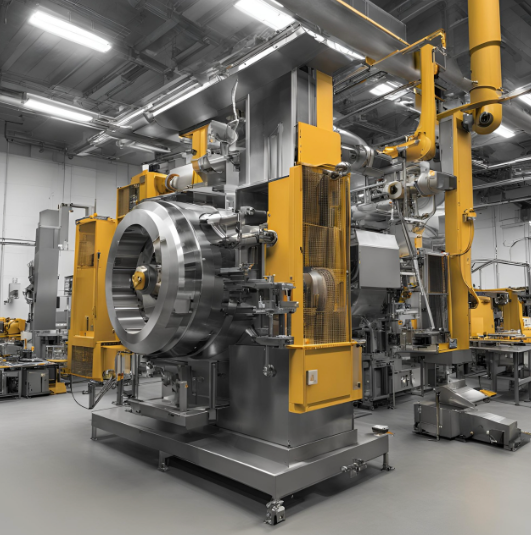

Why Lubrication is Crucial for Rotating Machinery

At the heart of industrial operations, rotating machinery drives the productivity and efficiency that industries depend on. The critical importance of lubrication in these systems cannot be overstated. It serves as a fundamental mechanism for reducing the friction that occurs between moving components. Friction is not just a minor inconvenience; it’s a major antagonist to machinery, leading to unnecessary wear and tear that can significantly reduce the longevity of expensive equipment. This reduction in friction facilitated by proper lubrication directly translates to a decrease in the heat produced during operation. Excessive heat can be detrimental, causing components to expand, deform, or even fail, which underscores the importance of maintaining an optimal temperature through effective lubrication.

Further deepening the significance of lubrication is its role in preventing the entrance of contaminants. In environments where equipment is exposed to potentially damaging elements such as dust, moisture, and debris, a well-lubricated system acts as a barrier, protecting sensitive parts from contamination. This protective layer can help preserve the integrity of the machinery, ensuring that it operates at peak efficiency and is less susceptible to unexpected breakdowns.

Moreover, lubrication plays a significant role in energy conservation. When equipment operates under conditions of high friction, it requires more power to perform the same tasks. Adequately lubricated machinery operates more smoothly and with less resistance, leading to substantial energy savings over time. In a world where energy efficiency is increasingly prioritized, the role of lubrication in reducing operational costs and environmental impact cannot be overlooked. This aspect of lubrication management aligns with the reader’s interest in reducing operational costs and environmental impact.

However, it’s not enough to simply apply lubricant; it must be the correct type, applied in the right amount, and at appropriate intervals. The specific requirements for lubrication vary widely depending on the type of machinery, its operating conditions, and the demands of the industry it serves. This necessitates a strategic approach to lubrication management, ensuring that the chosen lubricants provide the maximum benefit, enhancing performance and extending the operational life of rotating equipment. This emphasizes the need for specialized knowledge and expertise in lubrication management.

The Consequences of Poor Lubrication Practices

The ramifications of neglecting proper lubrication practices in the maintenance of rotating machinery are far-reaching and can severely impact operational efficiency and financial health. Unscheduled downtime due to equipment failure can be costly. According to Plant Services, effective lubrication maintenance can decrease downtime by as much as 20-30%, ensuring that operations run smoothly and without interruption. Your vigilance in ensuring sufficient lubrication, or the use of appropriate lubricants can prevent increased friction between moving parts. This heightened friction not only accelerates wear but also raises the temperature within machinery, escalating the risk of overheating and component failure. Your actions can prevent such conditions that not merely degrade the equipment’s performance but can precipitate premature failure, demanding costly replacements or extensive repairs.

In the realm of operational consequences, inadequate lubrication directly correlates with an uptick in downtime. Machinery taken offline for unscheduled maintenance disrupts production schedules, leading to missed deadlines, decreased output, and potential breaches of contract. The financial implications are multifaceted: immediate repair costs are compounded by the loss of revenue during downtime, and the longer-term impact of customers losing faith in the reliability of services provided.

Furthermore, the absence of a proper lubrication regimen invites corrosion and the accumulation of contaminants within the system. These intruders can severely damage critical components, compromising the machinery’s integrity and functionality. Over time, the cumulative effect of these factors not only shortens the lifespan of the equipment but also necessitates more frequent interventions by maintenance teams, diverting resources from other critical areas of operation.

Safety issues are another dire consequence of poor lubrication practices. Equipment failure can pose serious risks to personnel, potentially leading to injuries or worse. The legal and financial consequences stemming from workplace accidents, such as heightened insurance costs and the possibility of legal disputes, can place additional pressure on an organization’s resources.

The ripple effects of such negligence underscore the critical nature of establishing and adhering to a comprehensive lubrication strategy. It’s a cornerstone for maintaining not only the operational efficiency and reliability of rotating machinery but also for safeguarding the financial stability and reputation of the organization at large.

The Benefits of Advanced Fluid Management

In the realm of rotating equipment maintenance, the adoption of advanced fluid management systems represents a significant step forward in optimizing operational outcomes. Cutting-edge systems like automatic lubrication and condition monitoring technologies are pivotal in transforming the role of lubrication, enhancing equipment efficiency, and prolonging its lifespan.

Automatic lubrication systems are engineered to deliver the right amount of lubricant at the right time to critical components, thereby eliminating the guesswork and potential human error associated with manual lubrication. This precision ensures that each part receives optimal lubrication, reducing the wear and extending the service life of the machinery. Ensuring a consistent application of lubricant is crucial for preventing both over and under-lubrication, which are common causes of equipment failure and expensive unplanned downtime.

Condition monitoring technologies further enhance fluid management by offering real-time insights into the condition of lubricants and machinery. These systems can detect changes in lubricant properties, such as viscosity and contamination levels, that may indicate developing issues within the equipment. Maintenance teams can proactively tackle potential issues before they develop into significant failures by recognizing these early warning signs. This proactive approach to maintenance not only reduces the likelihood of equipment breakdowns but also allows for more efficient scheduling of maintenance activities, minimizing disruption to operations.

Additionally, advanced fluid management solutions contribute to environmental sustainability by optimizing lubricant use and reducing waste. Precise application and condition monitoring ensure that lubricants are only replaced when necessary, rather than on a predetermined schedule. This not only conserves lubricant but also reduces the environmental impact associated with lubricant disposal.

By integrating these advanced fluid management solutions, industries can achieve a host of benefits, including improved equipment reliability, reduced maintenance costs, and enhanced operational efficiency. The implementation of such systems signifies a move towards more sustainable, efficient, and cost-effective maintenance practices that are essential in the competitive landscape of industrial operations. These technologies enable industries to navigate the complexities of lubrication and fluid management with greater ease and precision, paving the way for a future where machinery downtime is significantly reduced, and operational excellence is the norm.

Partnering with Lubrication Specialists: What You Need to Know

Engaging with external lubrication experts brings a wealth of advantages to any industry reliant on rotating equipment. These experts hold profound knowledge in lubrication science and boast extensive experience spanning various sectors, ranging from manufacturing to agriculture and beyond. Their invaluable expertise is instrumental in navigating the intricate demands of diverse machinery and operational settings, guaranteeing that lubrication strategies are meticulously tailored to address specific requirements.

One critical service that lubrication specialists provide is the formulation of customized lubrication solutions. Given the diversity of machinery and the conditions under which they operate, there is no one-size-fits-all lubricant. Specialists can develop custom lubrication programs that enhance the performance and longevity of each piece of equipment, taking into account factors like operating temperatures, load pressures, and environmental conditions.

Furthermore, lubrication specialists are adept at conducting thorough lubricant analyses. This involves examining the properties of lubricants in use, such as their chemical composition, viscosity, and contamination levels. By conducting such analyses, specialists can pinpoint potential issues before they escalate into costly problems, enabling timely interventions to keep equipment in optimal condition.

Training for maintenance personnel is another area where lubrication specialists add significant value. They can equip your team with the latest knowledge and best practices in lubrication management, from selecting the right lubricant to understanding the correct application techniques and intervals. This empowerment of on-site teams contributes to a culture of proactive maintenance, reducing the likelihood of equipment failure and extending the service life of machinery.

In essence, partnering with lubrication specialists is a strategic move for any industry dependent on rotating equipment. Their expertise not only enhances the effectiveness of lubrication programs but also supports the overall goals of improving reliability, efficiency, and cost-effectiveness in equipment maintenance. By leveraging the skills and knowledge of experts, organizations can achieve a competitive edge, ensuring their machinery operates smoothly and reliably in the pursuit of business success.

Future Trends in Lubrication and Fluid Management

The horizon of lubrication and fluid management is marked by groundbreaking developments, signaling a transformative phase for industries reliant on rotating machinery. Predictive maintenance strategies are gaining traction, powered by advancements in data analytics and machine learning. These strategies leverage data collected from equipment sensors to predict wear and lubrication needs before they become critical issues.

By anticipating machinery failures, companies can optimize maintenance schedules, minimize downtime, and prolong the lifespan of their equipment. This predictive approach marks a significant departure from reactive maintenance models. It presents a more efficient and cost-effective solution for handling lubrication requirements and guaranteeing equipment reliability.

Internet of Things (IoT) enabled lubrication systems represent another cutting-edge trend. These systems enable real-time monitoring and control of lubrication processes from remote locations, offering unprecedented precision in the delivery of lubricants to machinery components. IoT technology facilitates the automatic adjustment of lubrication parameters based on real-time data, ensuring optimal performance and reducing the risk of lubrication-related failures. The integration of IoT in lubrication practices underscores a move towards more intelligent, autonomous systems that can enhance operational efficiencies and contribute to smarter, more responsive maintenance protocols.

Together, these trends illustrate a future where lubrication and fluid management are more sustainable, predictive, and intelligent, offering a pathway to reduced environmental impact, enhanced equipment performance, and greater operational efficiency.

Contact us to discuss how IFM can help with your rotating equipment lubrication practice improvements.