Having a poorly designed lubrication practice impacts efficiency and thus the bottom line. Whether or not you are looking to bring in outsourced lubrication experts, understanding how to calculate the potential savings and benefits of a well designed lubrication practice is critical in helping you make better decisions on how to increase efficiency. In part 1 of a 2 part series, we will cover how to estimate this potential savings.

Potential Savings Estimation

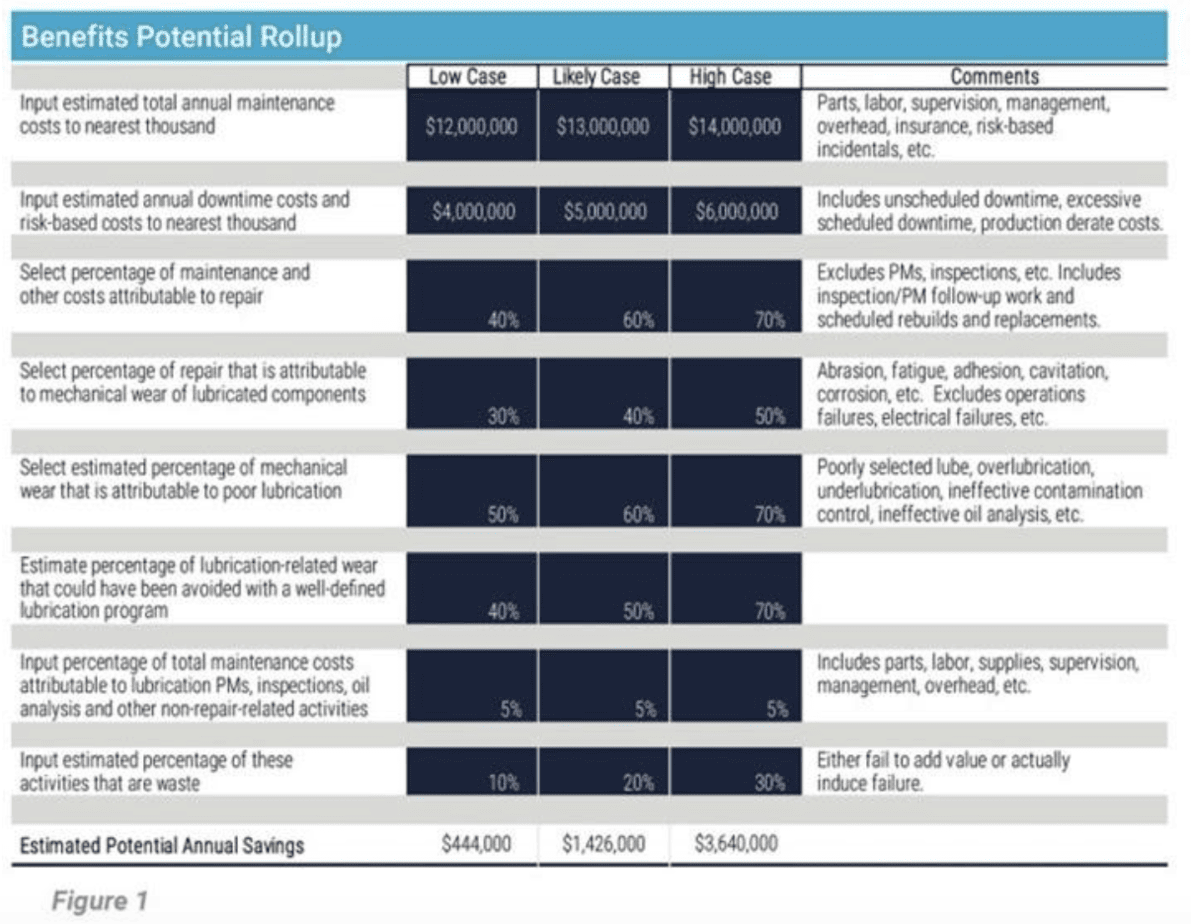

One cost attribute to consider is the cost of inefficiency associated with deploying a poorly designed lubrication practice. “While the effect of poor design (for example, incorrect regrease frequency, volume, and product selection) is accounted for in the repair opportunity costs, you must also recognize the wasted time and effort associated with that design.” (Source: Reliable Plant)

“This value is derived by estimating the percentage of the maintenance budget associated with lubrication PMs and other lubrication-based non-repair activities (X, including labor and materials) and then estimating the percentage of this value that is unnecessary (Y).” (Source: Reliable Plant)

.Opportunity costs (inefficiency) = (maintenance cost) x X x Y

Using the example in Figure 1, it is estimated that based on an annual maintenance budget of $13 million and estimated annual downtime costs of $5 million, we have a total of $1,426,000 in repair and inefficiency costs that can be eliminated through a well-designed, well-executed best practices program.

So, what’s the result? In the case of these hypothetical plants, the annual savings range from $444,000 to $3 million or more.

When most companies go through this exercise, they are shocked by the results. Making similar estimates for your plant can help show the dollar value of lubrication improvements to leadership or other influencers in the organization. With the lubrication improvements that a contract lube technician can bring, these savings may help you cost-justify bringing in outsourced help.

Contact us to discuss how IFM can help with your lubrication practice improvements.