-

What is Varnish?

Lubricant varnish, also known as lacquer, tarnish, tar or sludge is a byproduct of lubricant oxidation and degradation. While varnish typically presents itself as a yellow or brown colored sticky substance, it can manifest in many different colors, textures, and chemical compositions depending on the root cause.

-

How to tell if you have varnish?

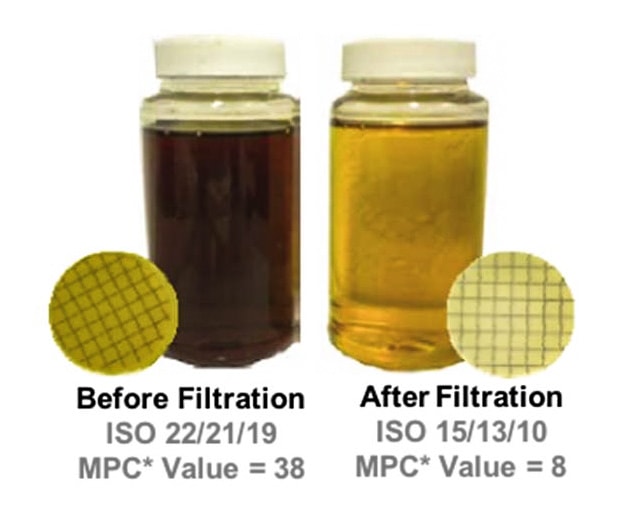

While the above-listed symptoms are good indicators of an existing varnish problem, the technology exists to help analyze the potential of varnish formation. These oil analysis test methods include but are not limited to:

- Membrane Patch Colorimetry (MPC)

- Ultra Centrifuge

- Microscopic Particle Counter

-

What causes varnish in lube oil?

While the cause of varnish is typically the thermal stressing of the oil, other factors such as contamination, additive fallout, and other chemical reactions can cause varnish to form on the internal metal surfaces of hydraulic and lubricating oil systems.

-

How to remove varnish?

While there are a few different methods of removing varnish from a lube oil or hydraulic system, there are a few different things to consider when deciding on the right tactic. Different methods have been proven to be more successful at removing varnish than others depending on the chemical composition of the varnish, the condition of the oil, and the location of the deposits.

-

What problems are caused by varnish?

While decreased lubricant life and varnish deposits are some of the most obvious symptoms of varnish, the following represent common problems caused by the presence of varnish in a hydraulic or lubricating oil system:

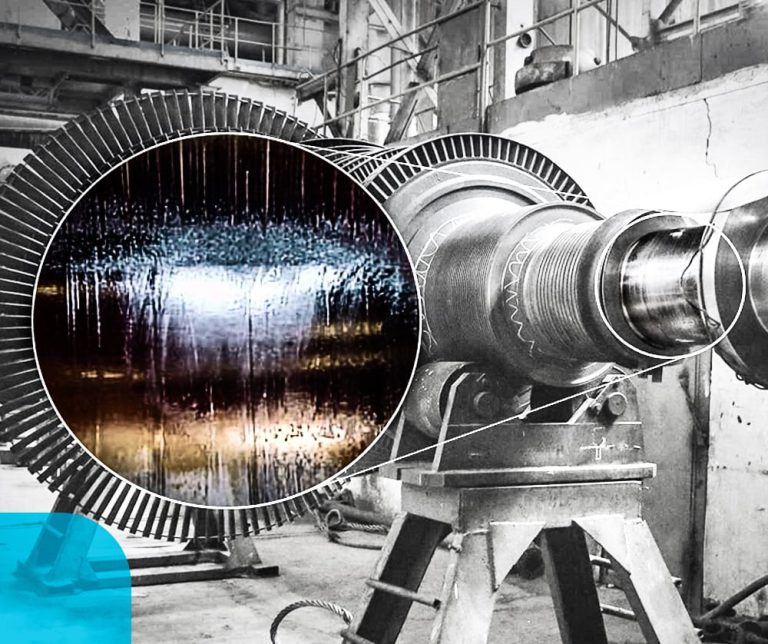

- Journal bearing failures — Varnish prevents oil from performing most of its lubricant functions including; cool surfaces, prevent wear, prevent oxidation, and transfer contaminants to filters, leading to bearing failures.

- Filter Plugging — Once the varnish has taken away the solvency of a lubricant, filters will quickly begin to plug with degradation byproducts such as varnish.

- Flow Restriction — Not only will filters begin to plug but varnish deposits will begin to restrict flow in small orifices and strainers.

- Restriction and sticking of moving parts — such as servos, directional valves, and other mechanical parts.

- Component Wear — Varnish does a great job of attracting hard particles and causing them to stick to the surface of lubricated components. This will promote component wear.

- High Bearing Temperatures/System Tripping — Varnish has a thermal insulating effect on metal surfaces, especially bearings where the oil is intended to not only lubricate but dissipate heat from the surfaces of the bearings.

- Decreased Oil Life /Oxidation — Varnish is an auto-catalytic reaction that leads to accelerated oxidation and loss of an oil’s useful life.

-

What are the methods to remove varnish?

- Ion Resin Exchange Media Filtration

- Depth Media Filtration

- Chemical Cleaning

- & more